Empowering tomorrow’s solutions through innovation

Investing in technology means prioritizing the quality of production, ensuring the safety of our staff, and fostering the growth of our company: in short, it means investing in the future. We firmly believe that research and development are essential to stay abreast of an ever-evolving market, ensuring we remain competitive and innovative.

Our aims have always been centered around maintaining control over every stage of production, from the design to the finished component, thereby reducing time-to-market and delivering tailor-made solutions to any customer. We are proud of the growing international recognition of our commitment to excellence, shown by the continued trust of leading global companies.

We have a powerful software capable of managing the entire production cycle. This allows us to assess the feasibility and predict the final results as early as the bidding stage, improving the efficiency of the following stages. All applications running on the machinery for die engraving, as well as on CNC centers, are CAD-CAM generated to allow maximum flexibility.

We design and produce in full autonomy both the forging dies and the machining tools needed to obtain the finished part. Our in-house die construction workshop is equipped with 9 machining centers and 2 CNC lathes capable of engraving dies suitable for our presses, up to a maximum size of 1300 mm x 550 mm x 400 mm high and 550 mm on round dies.

We have 6 lines for hot forging, 3 of which are robotized, equipped with mechanical presses from 1,600-ton up to 8,000-ton which allow us to produce parts weighing from 0,1 up to 180 kg in steel, and from 0,5 up to 40 kg in aluminum alloys: the greatest flexibility to meet the most various types and design needs.

We have furnaces capable of solubilizing duplex, super duplex, and stainless steels, as well as performing treatments on exotic alloys. We also cooperate with qualified suppliers for the heat treatment of carbon and alloy steels.

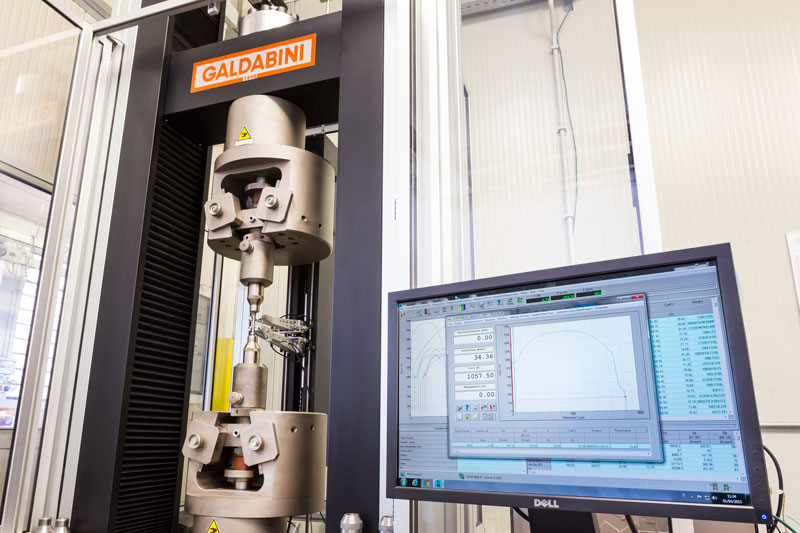

Our in-house destructive testing laboratory, compliant with ISO / IEC 17025: 2017, ensures the prompt analysis of the mechanical properties achieved after treatment. It is also equipped with a tensile testing machine and two pendulum impact testing machines to meet the requirements of both EN and ASTM standards, a spectrometer, a microscope, and a durometer.

Our mechanical machining department is continuously evolving, currently boasting forty CNC machines, including multitasking centers, vertical and horizontal machining centers. Having invested throughout the years in the best industrial machinery available on the market, we can guarantee accuracy and precision in every type of mechanical machining.

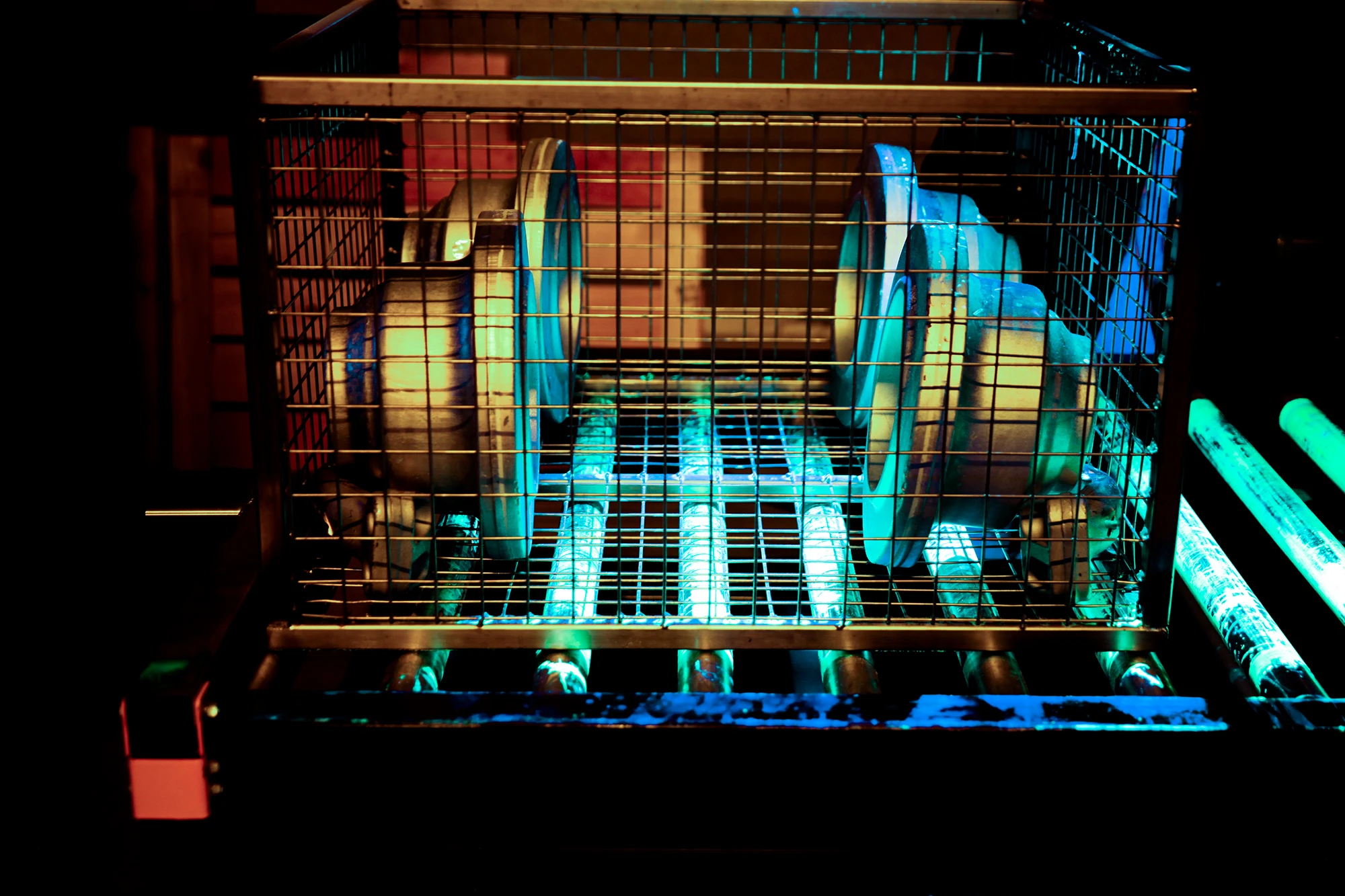

We have an entire building dedicated to nondestructive testing, equipped with 6 benches for magnetoscopic testing, 1 semiautomatic line for liquid penetrant testing, and 1 line for the color contrast PT method to verify the integrity of components after forging and heat treatment. All our control operators are qualified to ISO 9712 level II standards.

Surface treatments include a range of processes applied to the surface of a metal to enhance its properties, such as appearance, hardness, corrosion and wear resistance. These treatments are essential in various applications to improve the performance and longevity of metal products.

Before any component is approved for distribution, it undergoes rigorous testing and inspections. This phase ensures that each piece meets the highest standards of precision, strength, and safety. We have a metrology lab equipped with three coordinate measuring machines and a 3D laser scanner for dimensional checks on both raw and machined parts. It is through these rigorous procedures that we can guarantee a finished product of flawless quality.

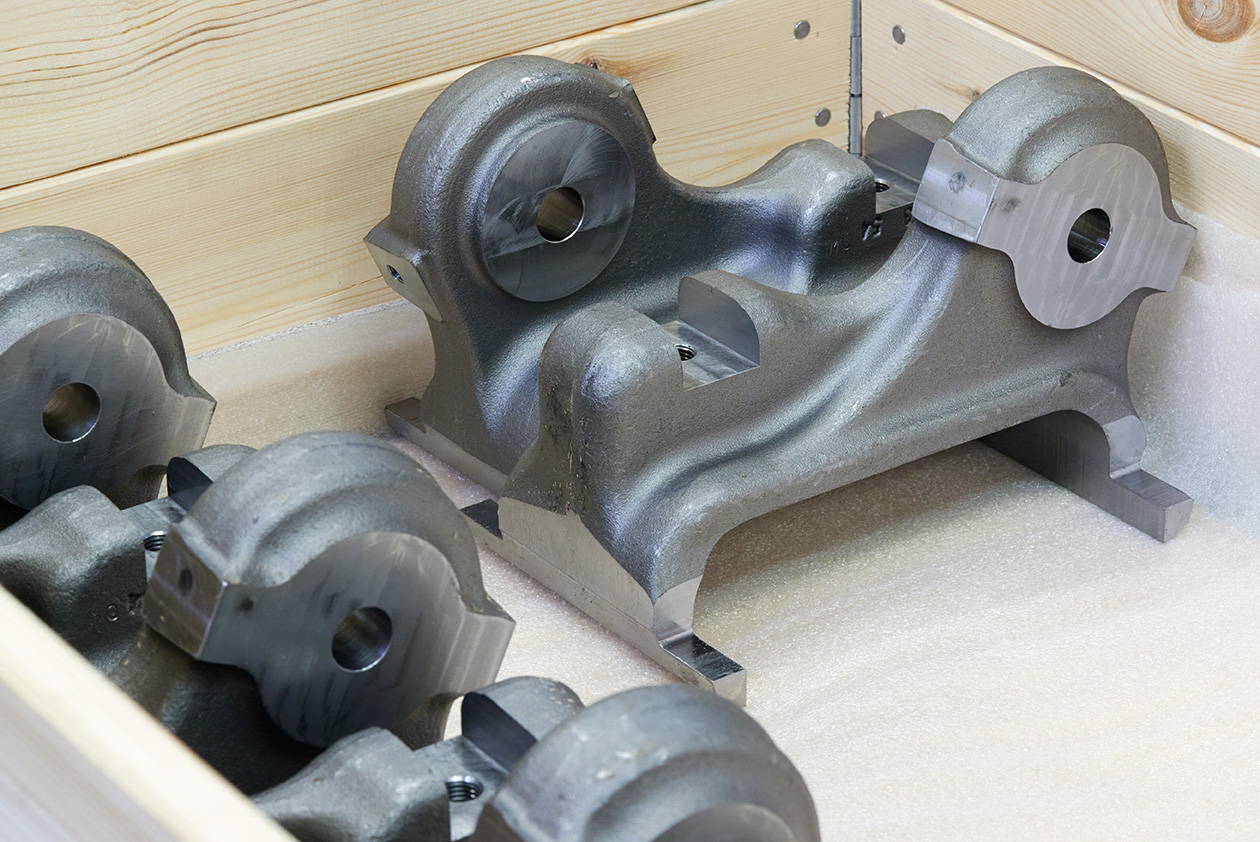

Each item is carefully packaged using high-quality materials that provide adequate protection during transit. Our packaging process is designed to minimize the risk of damage and ensure that products arrive intact and ready for use. We prioritize customer satisfaction and strive to provide a seamless experience from order placement to delivery.